Our Solutions

- Design Support, also in the pre-development

- Projectmanagement

- Rheologie and simulation of mould concepts

- Mould design and production

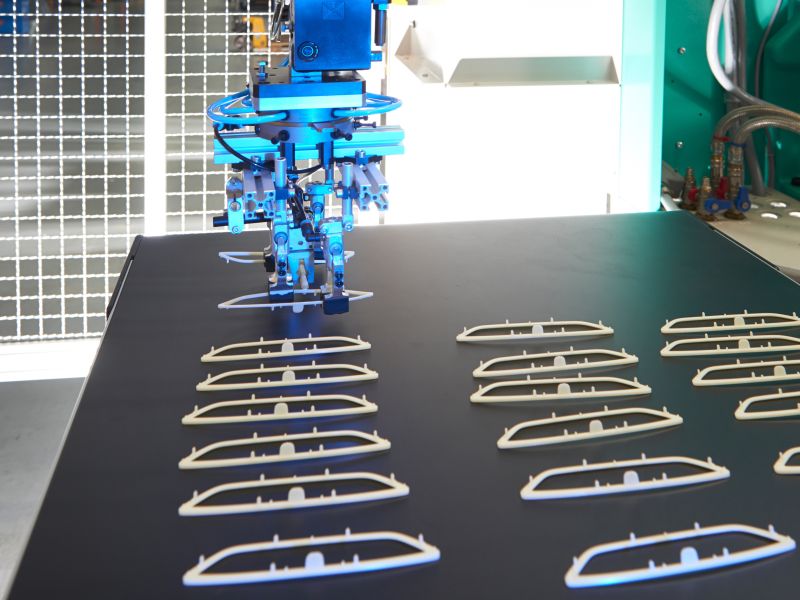

- 25 mondern injection maschines (Arburg, Demag, Engel)

- 1K - 40 t. up to 400 t.

- 2K - 150 t. L-Position with turntable

- 2K – 350 t. & 800 t. V-Position with turntable

- 100% equipped with extraction gripper

- Central materialsupplier and drying

- mobil plasmasystem

- Own toolshop for maintenance and repairs

- Machines with up to 2300 tons of force available in our group of companies

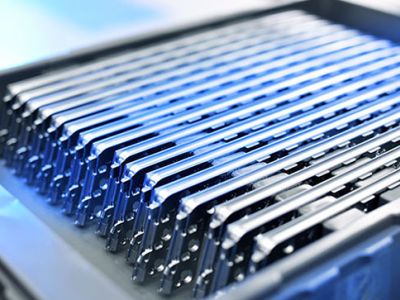

- Modern, synchronized electroplating system with a production bath of 2.8 m wide and 1 m deep

- 1K and multi-component in parallel process in the electroplating system

- Parallel process for various OEM-specific shades, including gloss and matt shades

- Fully automated dosing

- Approx. 100,000 parts or 1,200 m² coated surface per day

- Cr-III finish & Cr-VI in parallel process

- Modern test laboratory with wet chamber and in-house process monitoring

- Modern, flexible wastewater management according to the state of the art

- Optical inspection of demanding surfaces

- Autovisual control for the highest quality standards in use since 2019

- Expansion to include AI control algorithms in 2025

- Reworking & assembly

- Lasertreatment & further customization of components, for example brushes

- MCE laser process, enables the insertion of textures, optical offsets and customizations

- Logistic services

- Development, production and supply of packaging, multi- and oneway variants

- Logistic planing

- Organization and execution of transports

Contact

DKS Surface GmbH

Auf der Wahnsbach 3

56368 Katzenelnbogen

Germany

Fon: +49 6486 91 30-0

Fax: +49 6486 91 30-48

E-Mail: info@dks-surface.de

Terms and Conditions of Sales and Delivery (PDF)

General Terms and Conditions of Purchase (PDF)